Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Temperature and viscosity, physical and chemical properties, processing capacity per unit time, moisture content of filter cake, solid content in filtrate, washing degree of filter cake, etc. The model size (filtration area and filtration chamber volume) is mainly selected by analogy and laboratory tests.

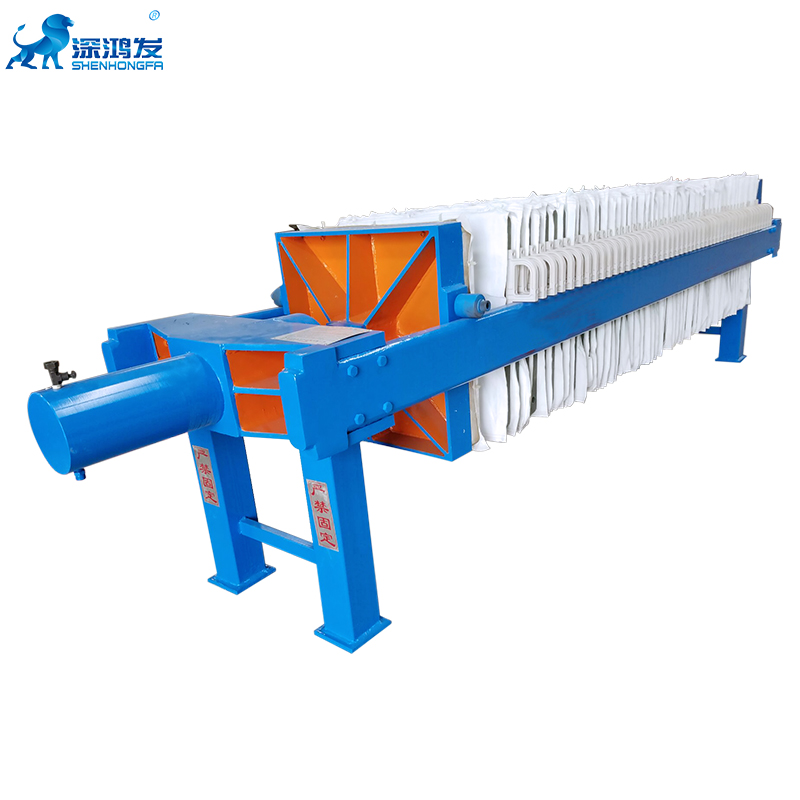

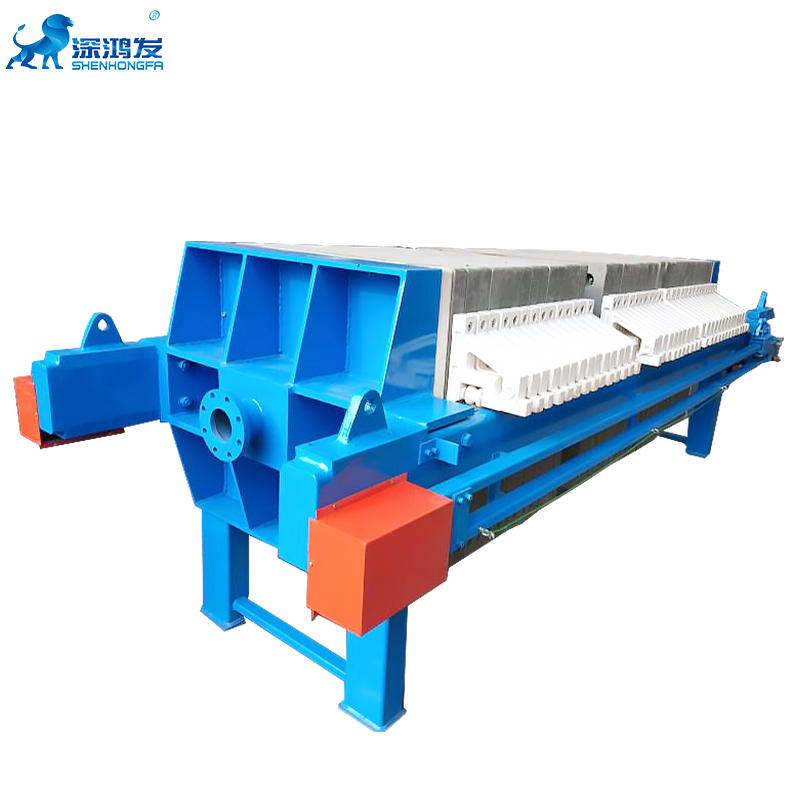

Plate and frame filter press is a kind of pressure filtration intermittent operation of filtration equipment, it is composed of the pressing part, the thrust plate, the pressing plate, the beam, composed of a frame, all the filter plate and the filter frame alternately superimposed on the two equal support beam, all the wave plate and the corresponding part of the filter frame have a liquid channel, used to introduce suspension or discharge liquid. The filter cloth is sandwiched between the sealing surface of the plate and the sealing surface of the frame, which becomes a sealing gasket in the filter plate and the sealing surface of the frame. The filter surface supporting the filter cloth is covered with grooves, and all grooves are communicated with the filtrate discharge channel. A filter press is composed of many parallel filter chambers. On both sides of each filter chamber are filter cloth layers that prevent the passage of solid particles in the suspension and allow the filtrate to penetrate. The total filtration area of these filter plates represents all the production capacity of the filter press.

Plate and frame filter press

Is composed of a filter plate and a filter frame, can withstand the filter pressure is low (usually less than 06Mpa) each equipment. According to the size of the area, the number of plate and frame is different. Plate and frame filter press is generally used for materials containing less granular objects filter, often used for fine product filtration, can be added on the back of the filter cloth filter paper.

Chamber filter press

A single filter plate is thicker than the plate frame filter plate, that is, the side filter press is made of two identical filter plates. When pressed, a filter chamber is formed between the two filter plates for storing granular objects isolated by the filter cloth. The feed hole is placed in the center of the filter plate, which is generally used for materials with more granular objects, such as sewage treatment, beneficiation, coal washing and other industries. The characteristics of the van filter press is not to cause the bias of the filter chamber, so that the filter plate should not be damaged, the filtration speed is fast, the slag unloading is convenient, the filtration pressure is large, the liquid content of the filter cake is low, can bear the filtration pressure up to 3.0Mpa, easy to realize the automatic pull plate unloading, adapt to a wider range, can make the largest filter press.

July 25, 2023

July 20, 2023

March 23, 2023

Contactar proveedor

July 25, 2023

July 20, 2023

March 23, 2023

Realizar consulta

Ms. Ada

Número de Teléfono:0086-13544177648

Fax:0755-81781055

Móvil:+8613544177648

Email:ada@hongfafilterpress.com

Dirección:NO.3 Aoxiang Road, Zhangbei Second Village, Ailian, Longgang District, Shenzhen,, Shenzhen, Guangdong

Sitio movil

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.